Plant Floor Solutions

The Evolution of Industrial Control Systems for Agile, Flexible and Digital Manufacturing Transformation Solutions

RTS specializes in providing high-value control systems to automate manufacturing cells and processes using the latest industrial technologies. Our 30+ years of manufacturing experience across a wide range of industries, has positioned us well to help you identify opportunities for improvements in all operational areas using extensive and granular production data analysis to achieve manufacturing excellence.

Whether you want to reduce operating costs, improve efficiencies, add capacity or improve your competitive position in the market, RTS is your single-source solution provider for all of your manufacturing industrial control and digital transformation needs.

Our Areas of Expertise

- Plant Floor Control Systems, PLC and SCADA Programming

- Electrical Controls Design and Control Panel Fabrication

- AI/ML – Prescriptive Manufacturing Insights from the Data

- Shop Floor Data Collection with Historian & Cloud Data Lake Deployment

- FAT, SAT, Commissioning and Instrumentation Services

- IIOT – Connect New Shop Floor Manufacturing Data to Unlock New Value

- Production KPI Benchmarking, Improving Manufacturing Performance

RTS CONSULTING – AUTOMATION HAS EXPERIENCE WORKING ON MOST PLC AND SCADA TECHNOLOGY SOFTWARE AND HARDWARE PLATFORMS.

Plant Floor Solutions

Turn-Key Automation Contractor

Our expertise in automation and systems integration allows RTS to offer our unique abilities as a single-source provider for client automation projects. We deploy turnkey shop floor control system solutions, from plant floor networking to cloud-based data lakes, which hold all of your plant’s relevant data. All helping to foster an increased ROI via digital transformation while lowering the total cost of ownership.

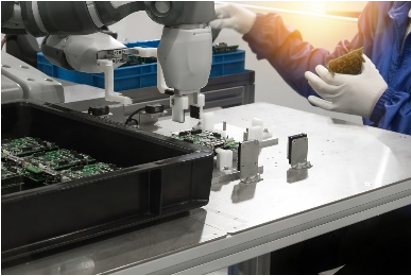

Some advantages that can be realized by implementing advanced technology include:

- Data transformed into actionable intelligence.

- Increased productivity/throughput.

- Tighter quality control.

- Higher asset utilization, efficiency/OEE.

- Reduction of labour costs.

In today’s ultra-competitive manufacturing environment, companies that do not invest in integrated plant automation will be left behind. In the early days the focus was on PLC and SCADA automation simply to replace relay control logic to increase reliability and reduce costs. Now the focus has shifted to increasing flexibility and agility in the manufacturing process. Manufacturers are increasingly demanding the ability to easily and quickly switch manufacturing products on the same line based on changing consumer demands. Today, decision support via data analysis with prescriptive insights is a must to lead the pack.

Let our staff of experienced engineers and programmers assist you with your shop floor solution needs.