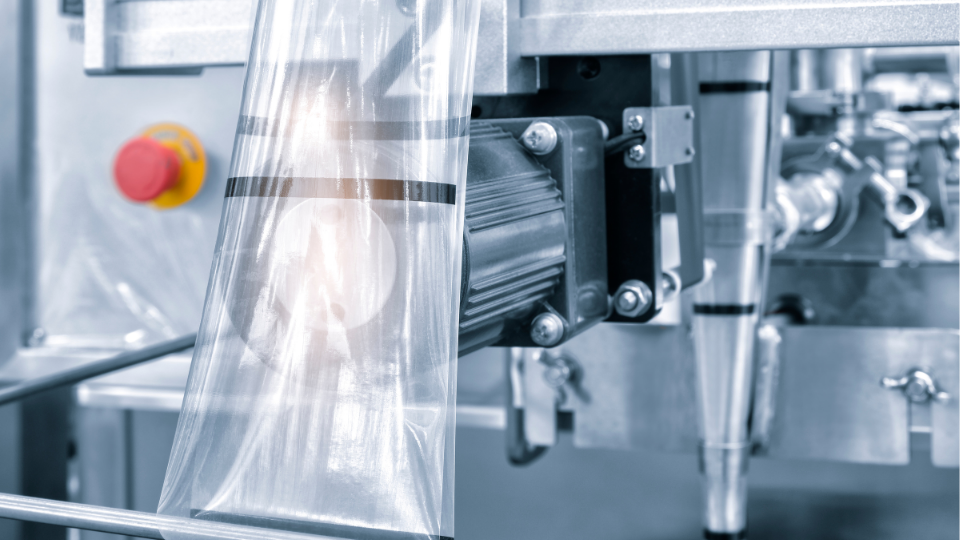

INDUSTRY

Plastics

Plastic manufacturers are increasingly adopting MES solutions with RTS to streamline production, reduce costs, enhance product quality, and embrace smart technology, ensuring a competitive edge in the industry.

Boosting Shop Floor Efficiency

Plastic manufacturing companies, including those in injection molding, extrusion, rotational molding, and blow molding, face increasing pressures to optimize production and reduce costs. RTS MES solutions offer:

- Improve decision-making with live insights into your operations.

- Leverage data to foster continuous improvement and boost productivity.

- Easily integrate MES with your existing systems to streamline operations and improve efficiency.

Our Impact:

- Simplify operations with RTS Mold and Die Management solutions, ensuring seamless tracking and maintenance.

- Empower employees with real-time data to reduce waste and improve decisions.

- Boost efficiency, cut costs, and enhance quality with analytics and automation.

Core Benefits

Real-Time Production Visibility

Track and monitor operations across the shop floor in real-time. Identify micro-stops, equipment failures, or inefficiencies before they affect production, and take immediate corrective action.

Continuous Improvement Culture

Our MES solutions promote a culture of continuous improvement by providing real-time insights, helping teams stay focused on efficiency and reducing manual interventions.

Yield Optimization & Cost Reduction

Reduce yield loss and delays, cut material waste, and improve OEE and plan attainment.

Quality Control & Traceability

Automate checks and real-time tracking to reduce errors, ensure compliance, and improve transparency.

Key Features

Real-Time Data & Alerts

Monitor shop floor activities in real-time, identifying potential issues or inefficiencies before they escalate and receive immediate alerts for any quality or performance concerns.

Optimized Production Cycles

MES software helps manufacturers streamline production by analyzing trends in equipment performance, mold changeovers, and plant efficiency.

Efficient Resource Utilization

MES software helps manufacturers maximize the efficiency of their resources by tracking materials, equipment, and production processes in real time.

Comprehensive Quality Management

Real-time tracking of part checks and quality control processes, reducing human error and ensuring consistent quality standards across all production stages.

Our Proven Process

Assessment & Consultation: Understand your unique manufacturing challenges and goals.

Fit-to-Standard Solutions: Provide tailored MES solutions aligned with your operational requirements.

Implementation: Seamlessly integrate MES with existing systems while minimizing disruption.

Support & Optimization: Provide ongoing support and continuous improvement strategies.

Read

Read more about our services

Watch

Watch RTS Demo Implementation

Redefine Productivity.

Smart Tools for Smarter Manufacturing Operations.