Asset Management

Driving Asset Performance to Unlock its Full Potential.

Maximize Uptime, Safety, and ROI Across Your Asset Base

Organizations today need to maximize the value they get from physical assets to achieve business objectives. Whether you need to reduce unplanned downtime, implement risk-based maintenance, or improve equipment reliability, our services deliver real-world impact aligned with ISO 55000, best practices, and your unique operating context.

Our Approach

RTS combines industry expertise, field-level experience, and digital enablement to help you optimize the lifecycle of your physical assets. We work across operations, maintenance & reliability, engineering, finance, supply chain, information technology, human resources, and other support functions to align strategy, technology, and day-to-day execution.

Core Offerings

Client Outcomes

20-40%

Reduction in unplanned downtime

10-15%

Improvement in asset lifecycle cost performance

Safer, more compliant operations

Stronger alignment between maintenance, operations, and engineering

Foundations for predictive and AI-enabled maintenance

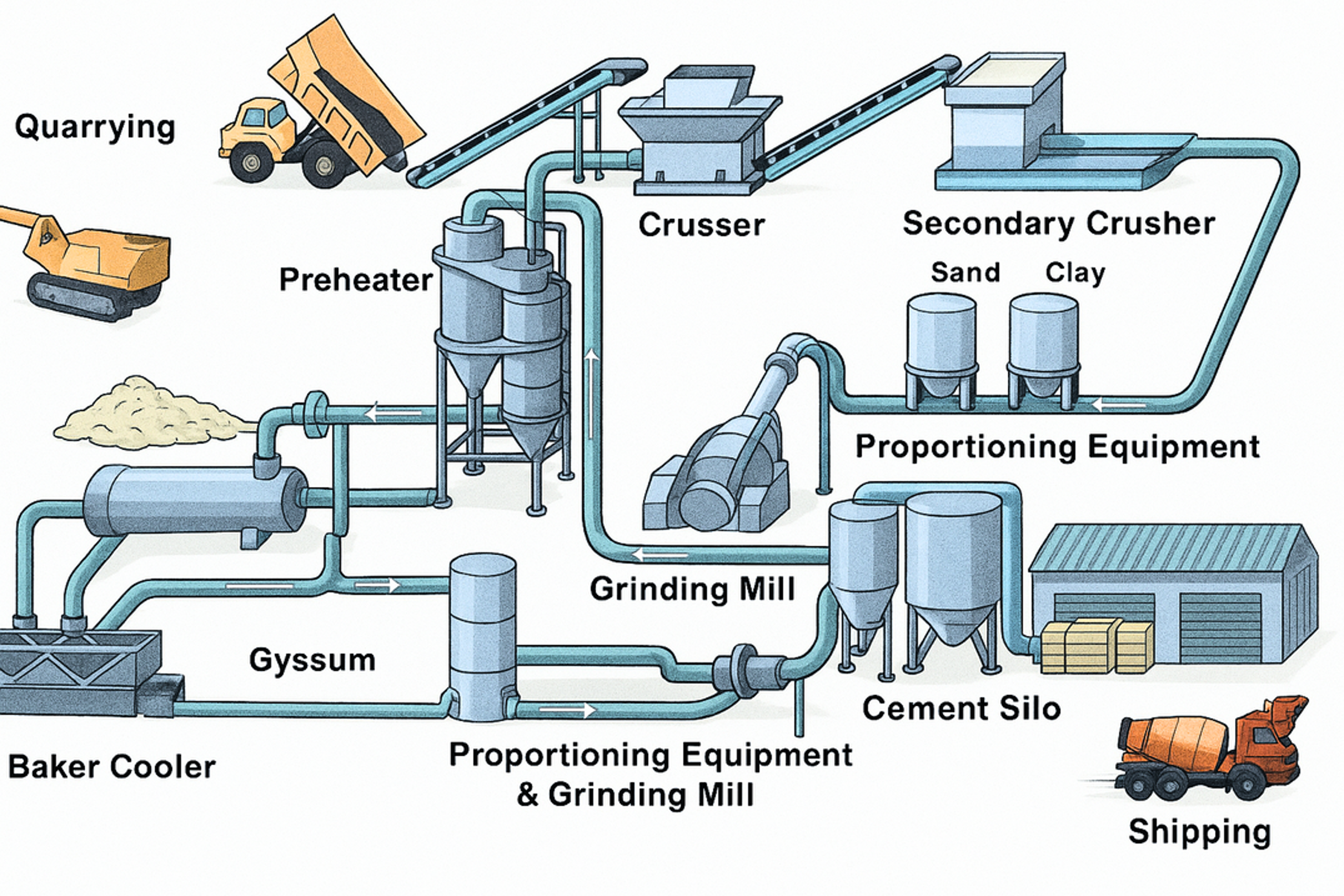

Asset Strategy & Reliability Engineering

We assess and optimize asset strategies to optimize performance, risk and cost. RTS applies proven methodologies such as: Criticality Analysis, RCM, FMECA, RBI, RAM, etc. to define maintenance, operations and parts strategies to optimize performance for the Life Cycle of Assets.

Key Activities (Click for more)

- Asset hierarchy and criticality analysis

- Failure modes, causes, and effects identification

- Strategy optimization for PM/PdM intervals and effectiveness

- Integration of reliability practices into CMMS/EAM systems

Outcomes (Click for more)

- Reduction in unplanned failures

- Prolonged asset life and reduced lifecycle costs

- Maintenance strategies that reflect real-world operating conditions

.

Key Focus Areas

Process mapping of work order lifecycle

Planning and scheduling role clarification

Backlog management and work prioritization

Schedule Load and Execution Compliance

Preventive Maintenance compliance

Wrench Time maximization

Outcomes

Increased planned maintenance execution

Reduced emergency and break-in work

Improved data quality and reporting for asset decisions

Work Management Optimization

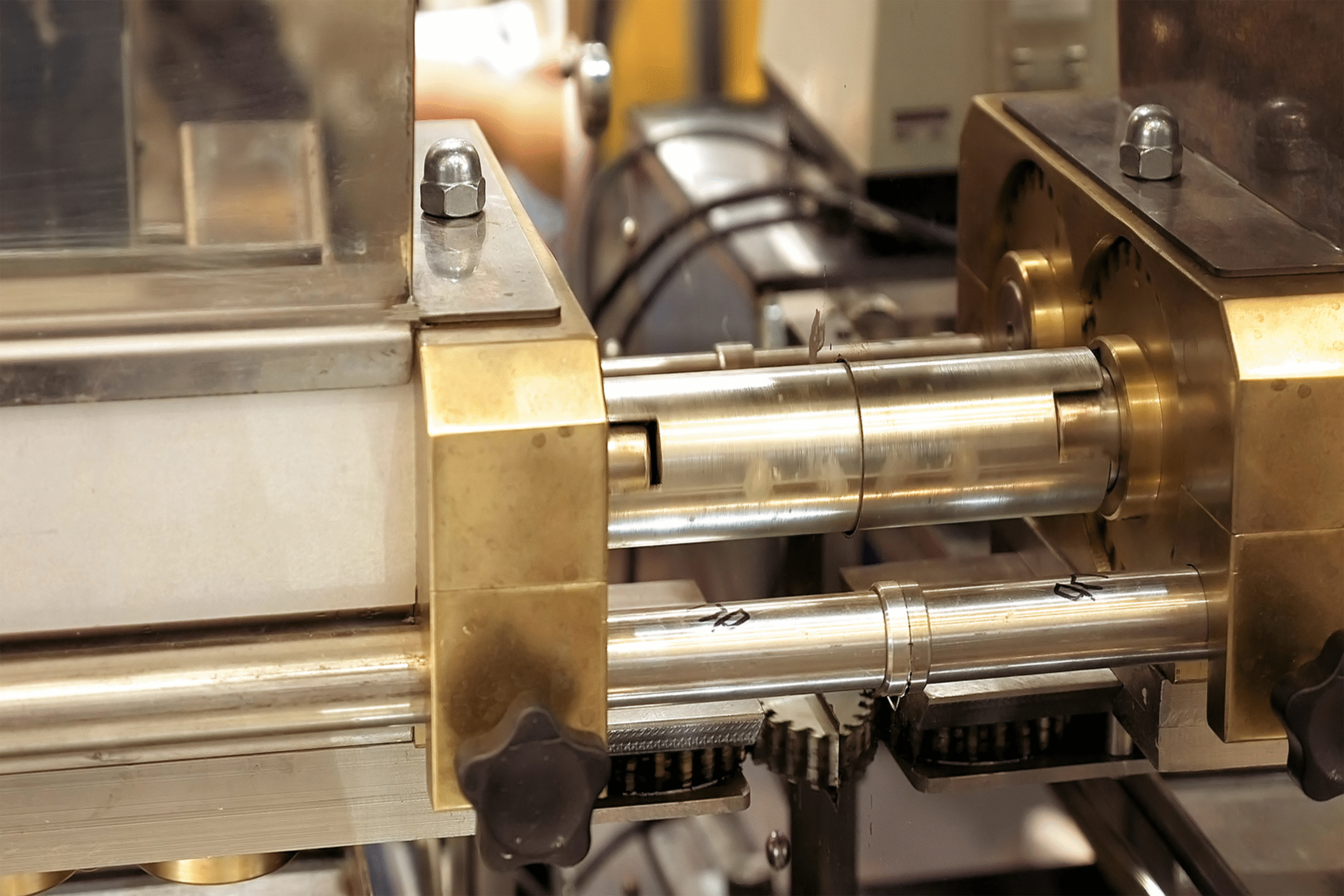

Effective maintenance execution depends on disciplined planning and scheduling. RTS works with clients to streamline work management processes and improve data integrity within existing CMMS/EAM platforms.

Operational Readiness & Commissioning

RTS ensures organizations are fully prepared for asset deployment and start-up. Our operational readiness services ensure your people, systems, and procedures are in place to operate and maintain assets reliably from day one.

Scope of Work

Equipment strategy development during design phase

CMMS/EAM data build-out (BOMs, plans, procedures)

SOP development and operator training

Commissioning support and defect tracking

Outcomes