Operational Excellence

Turn Everyday Operations into Strategic Advantage.

Drive Sustainable Performance with Operational Excellence

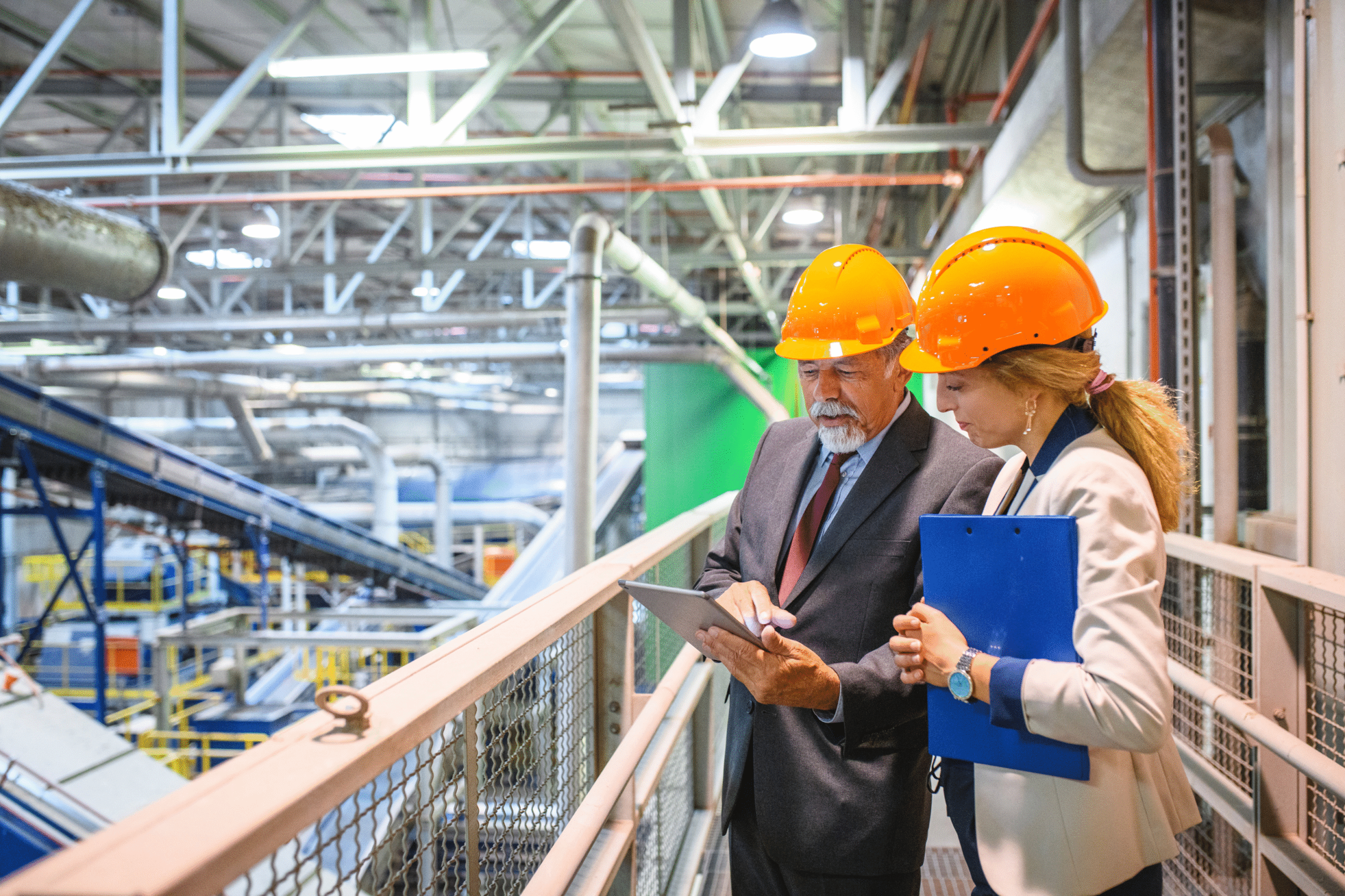

Today’s industrial operations face mounting pressure to deliver more with fewer resources, tighter timelines, and rising customer expectations. At RTS, we help clients build high-performing operations that are resilient, data-driven, and strategically aligned. Our Operational Excellence services blend industry-proven approaches like Lean, TPM, and Six Sigma with modern digital tools and cultural transformation programs, delivering both quick wins and long-term capability.

Our Approach

We don’t just optimize processes, we embed performance thinking into how your team’s work. RTS focuses on aligning strategy with execution, empowering front-line ownership, and using real-time data to drive continuous improvement.

Core Offerings

Operational Maturity Assessments

Baseline current performance, cultural readiness, and improvement opportunities across people, process, and technology.

Total Productive Maintenance

Build cross-functional ownership for equipment performance with autonomous maintenance, skills development, and early equipment management.

Strategy Deployment & KPI Frameworks

Align operational goals with corporate strategy using cascading KPIs, visual management, and accountability systems.

Digital Enablement

Layer in tools like dashboards, OEE analytics, and real-time visibility to enable smarter, faster decisions.

Lean Execution & Process Optimization

Reduce waste, improve flow, and embed continuous improvement using Lean and Six Sigma methodologies.

Sustainable Change Management & Culture Building

Train and coach leaders at all levels to drive accountability, engagement, and long-term ownership.

Client Outcomes

Structured daily management and tiered accountability

Stronger front-line engagement and problem solving

Enhanced visibility across operations

10-25%

Improvement in OEE and throughput

30%

Reduction in downtime and waste

Assessment

RTS offers structured assessments to benchmark your current operational performance across people, processes, systems, and culture. We identify strengths, gaps, and actionable opportunities to drive measurable results and sustainable improvement.

Key Activities

- On-site assessments and value stream mapping

- Interviews with leaders and front-line teams

- Maturity scoring across Lean, TPM, planning, and execution

- Data analysis to benchmark OEE, downtime, throughput, and quality

Outcomes

- Operational maturity report with prioritized improvement roadmap

- Quick wins and long-term initiatives tailored to your operations

- Defined KPI baselines and tracking framework

Total Productive Maintenance (TPM) Deployment

We help implement TPM programs that promote shared accountability for equipment performance. RTS supports the design and deployment of TPM pillars that reduce equipment losses and empower teams with structured, routine-based maintenance ownership.

Key Components

TPM pillar design deployment strategy customized to the specific operating context

Operating Standard definitions

Operator training and competency frameworks

Focused improvement workshops for chronic issues

Outcomes

Reduced breakdowns and minor stops

Increased operator ownership and engagement

Improved asset reliability and performance visibility

Strategy Deployment and KPI Alignment

Operational Excellence starts with alignment. RTS helps organizations cascade strategic goals into actionable KPIs and routines. We enable execution through visual performance management and tiered accountability structures.