Preventing Quality Issues Before They Occur

How are you ensuring continuous quality improvement across the entire product life cycle?

How fast are you able to respond when a quality issue arises? Does Operations have real-time visibility to quality trends?

Are prescriptive insights provided to operators enabling corrective actions before they cause product quality problems?

Quality management is not just about inspection activities and “after the fact” reviews to implement corrective actions. It’s about enabling and optimizing the quality strategy deployment with real-time actionable intelligence via a variety of tools (for example Ai) to trigger Corrective and Preventative Action (CAPA) from non-conformance production data.

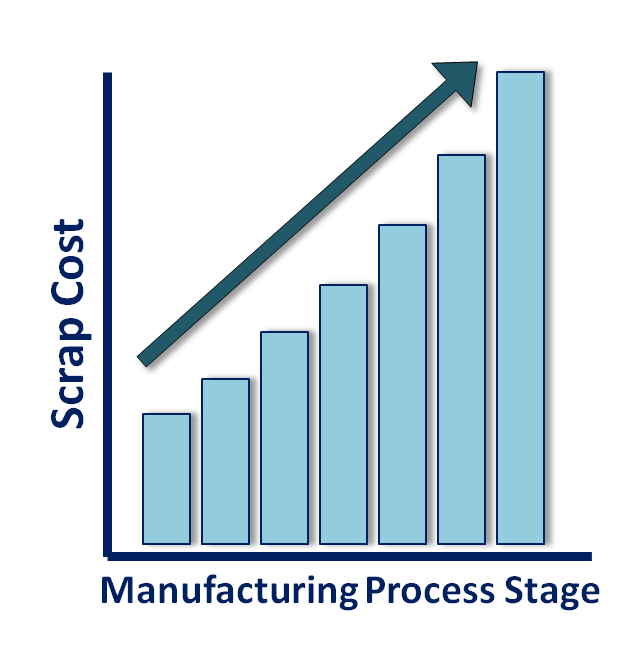

Whether the data is captured manually or automatically, analyzing it once the product has been manufactured, and failing to comply with customer’s “critical to quality” parameters, increases the level of scrap, rework, re-inspection and cost. All of these failures are the difference between “best in class” and “laggards” in quality management systems and manufacturing excellence.

So often companies have well-established inspection procedures, but without a holistic quality solution that integrates data from the shop floor with the comprehensive QM capabilities of SAP ERP and the new SAP Quality Issue Management (QIM) solution documenting quality issues, a closed-loop holistic quality management system landscape cannot be achieved.

So, how can you boost your customer satisfaction, reduce scrap and empower manufacturing personnel with real-time automated information on the shop floor to address quality issues as or even before they occur?

Quality Management Information System on SAP solutions (DM, MII, ME) creates a strategic advantage in only 8 – 10 weeks by providing:

Predictive Quality Management

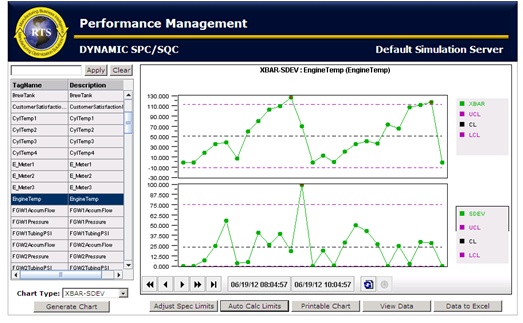

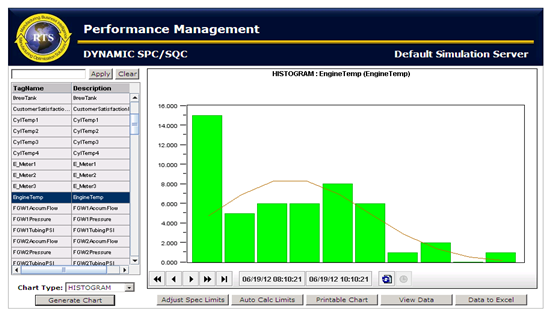

- Comprehensive visibility of real-time quality trending information to address quality issues before they occur.

- Actionable intelligence to address quality anomalies as they happen, driven by immediate e-mail alerts when quality control limits are exceeded.

- Ensured “critical to customer” specifications compliance, communicating customized production orders, customers quality information, and testing procedures to the shop floor.

- Enhanced decision making for raw material production suitability, by allowing visibility to inspection lot test results and providing instant notifications of “quarantined raw material” to shop-floor personnel.

Global and Integrated Solution

- One single system of record and analytics for quality management, consolidating information from different sources (SAP and non-SAP based) and processes.

- Increased data transparency & accuracy, automatically recording quality & production information from In-Line/Off-Line quality devices, Historians, PLC’s, DCS’s, LIMS & the business system.

- Effective quality analysis via standard and custom reports, including Statistical Analysis with automatic calculation algorithms for CPK, Median, Min, Max, Mean, PPM, Standard Deviation, Variance, and much more…

- Enhanced user acceptance and learning, through interactive role-based dashboards for different staff categories.

Increasing product quality with the use of SPC/SQC/Ai within SAP’s shop floor platforms (DM, MII, ME) allows transparency to quality and maintenance data in SAP ERP which can reveal root causes of product quality issues.

80% of all quality issues are repeat issues. Leading companies require the ability to capture, continuously improve, and leverage in-house knowledge from lessons learned so that focused preventive action can be taken to increase product quality.