Ignition Sepasoft MES

Interconnecting all aspects of manufacturing – delivering near real-time data and actionable insights.

Ignition Sepasoft MES is a Cost-Effective and Resource-Efficient MES which empowers manufacturers to streamline their processes with enhanced operational visibility. By delivering near real-time data and actionable insights, it boosts reliability, product traceability, and operational efficiency using solutions built on the Internet of Things (IoT).

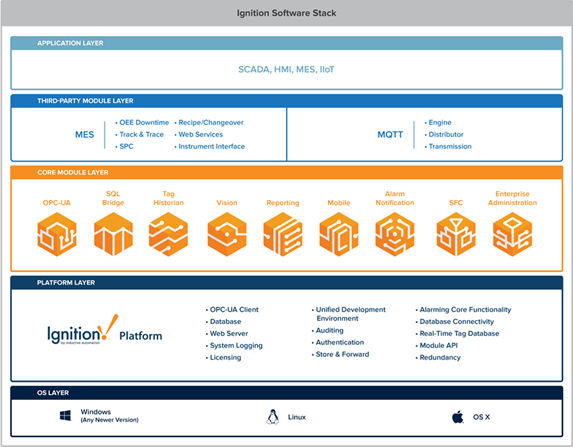

An MES solution serves as a pivotal link, aiming to bridge the gap among these diverse information sources. Its role involves establishing a two-way flow of information, enhancing the effectiveness of all existing systems by furnishing them with real-time data. The Sepasoft MES Product suite offers the necessary tools to achieve a seamlessly integrated system solution, if deemed necessary.

Unlike conventional MES systems that struggle to integrate diverse business processes, Ignition Sepasoft MES is designed to harmonize and interconnect all aspects of manufacturing, providing an advanced platform that avoids system gaps and mismatches. Simply exchanging data records between disparate systems is no longer sufficient. Today’s manufacturers need their systems to intelligently align, transforming data into valuable insights. By integrating big data, artificial intelligence (AI), and machine learning (ML) capabilities, Ignition Sepasoft MES extracts meaningful insights from shop floor data and beyond.

Benefits of Sepasoft MES Architecture

Manufacturers often require unique and tailored solutions, whether it’s tracking process data, managing materials, interfacing with specific ERP systems or PLCs, or defining customized KPI metrics. Variations exist even within the same organization, where different plants and departments demand specific adaptations. Sepasoft MES, in conjunction with Ignition, empowers you to craft a bespoke MES solution precisely aligned with your business requirements, accommodating diverse needs seamlessly.

Solution Capabilities

RTS have partnered with Sepasoft MES, an Ignition product, to co-develop cutting-edge MES/MOM functionality seamlessly integrated into the Ignition platform. Sepasoft boasts an impressive portfolio of MES/MOM applications, including the

Batch Procedure Module

OEE Downtime Module

Track & Trace Module

Settings & Changeover Module

SPC Module

Interface for Business Connectivity Module etc.

These modules are designed not only to offer competitive pricing but also to cater to the diverse needs of both system integrators and businesses looking to tailor their MES/MOM solutions.

Importantly, our approach is firmly rooted in open standards, empowering end-users to customize the software to precisely match their unique requirements.

Holistic Manufacturing Management with Ignition Sepasoft MES

Sepasoft MES operates across various functions, including:

Managing product definitions throughout their lifecycle

Scheduling resources

Executing orders, Analyzing production

Managing downtime to enhance Overall Equipment Effectiveness (OEE)

Product quality, and traceability

Sepasoft MES serves as the system of record, capturing data, processes, and outcomes of manufacturing, particularly vital in regulated industries like food and pharmaceuticals, where meticulous documentation is essential.

Positioned between Enterprise Resource Planning (ERP) and Supervisory Control and Data Acquisition (SCADA) systems, MES is tailored to the Plant Operations layer, offering flexible interactions with ERP and plant equipment.

It covers Production, Inventory, Quality, and Maintenance operations, with modules catering to each area.

It is the execution system on the factory floor, where operators directly oversee workflows for production or repair, including task lists, instructions, data collection, quality checks, and task completion verification.

Sepasoft MES streamlines workflows, provides visibility, and sends event notifications to align manufacturing with enterprise information needs. It eliminates non-value-added activities, improves data accuracy, and feeds real-time data to ERP for efficient processing, planning, and scheduling.

Sepasoft MES acts as a liaison between the factory floor, corporate engineering (PLM), and corporate planners/schedulers (ERP), facilitating data retrieval from ERP or PLM systems upon operator requests.

With Sepasoft MES, you can seamlessly integrate your ERP system, sharing production schedules across departments and accessing comprehensive data in a unified system, eliminating the need for manual report comparisons. Integrated documents facilitate data correlation during manufacturing processes, and all modules seamlessly integrate with Ignition HMI and SCADA software for centralized data access and collaboration.

With a comprehensive range of services, RTS Consulting Automation is your trusted partner for consulting, training, custom solutions, and systems integration. We help companies embrace the future of manufacturing through innovative, scalable solutions that drive efficiency and growth.