blog

Digital Transformation - Why does the Manufacturing Industries need it even more today?

Manufacturing today is no longer the same as it used to be. It plays a very important role in the overall digital transformation of any organization as it combines the data from all areas of the business; such as product design, planning and estimation, production, quality, supply chain, service, and operations. All these sectors work together intimately to find solutions to the challenges faced by manufacturing.

But why is it important for manufacturers to go ‘digital’?

Let’s consider an example:

Designers are executing their designs in a 3D CAD file, where they create a digital twin of the object they want to mirror and everything is connected via the Internet of Things (IoT). Drawings aren’t handed to an engineer anymore, they are being sent via email or their mobile devices. The fictional dream of a paperless factory is here for many and seems to be just around the corner for others.

But what does it means for the business in the manufacturing sector?

Look at how far we have come from physically receiving a letter in the mailbox to now receiving that same letter electronically in our email inboxes. Physical spreadsheets have been turned into Excel sheets or Google sheets and clay models into CAD drawings and so on. The process and systems more or less have remained the same but only have been digitized. Today, a signature can be done digitally and remotely. These are some of the examples of digitization in today’s world, but how does it trickle down to the manufacturing industry?

- Increase in manufacturing efficiency and faster go-to-market time!

How would you like the idea of a high-speed production line with minimal wastage? In today’s day and age consumers want their needs to be satisfied as quickly as possible. Companies have to adapt and deliver on the ever-changing taste and product personalization of the customer by quickly adapting to the established industry standards while lowering their overheads.

Digitization enables an organization to quickly launch a new product by boosting productivity while maintaining speed and accuracy to beat the most demanding deadlines.

Manufacturers would be able to move their new designs quickly from the design floor to the shop floor and also adapt any revisions if and when they come.

At the moment many of the manufacturing companies still adhere to older ways and their processes are manual in many cases. This contributes to lost time, wastage, quality issues and therefore lost business revenue.

Digitization helps an organization optimize its process and thereby reducing the wastage of resources: people, assets, inventory.

- Digitization and Industrial Internet of Things (IIoT) go hand in hand.

Imagine an industrial setup where each machine talks to the other continuously so that it can prevent a possible breakdown and thus lost production time. Exactly that is what is enabled by IIoT. Machines communicate real-time information to the plant supervisor about the maintenance required, wear and tear of the parts, the efficiency level of the plant, etc.

And with the help of digitization, all of this data is automatically recorded through business intelligence tools and dashboards to give the people in charge the ability to refine the process to increase the efficiency of the shop floor and ultimately the plant.

The point is the data that was earlier generated and could not be leveraged to increase the efficiency of the manufacturing process, which can now be used to increase productivity from almost a single screen.

The data can only be collected and utilized if the plant is digitized. The advantages of reduced human intervention shall lead to the following:

- Real-time, accurate data supporting quick business decisions

- Product modifications can be done to product online

- Changes can be rolled over to the production floor without interrupting the flow

- Production parameters could be changed automatically by sensing a change in the environment

- A more agile and flexible manufacturing process

In the future, automation and artificial intelligence will optimize the manufacturing process in response to real-world supply chain dynamics.

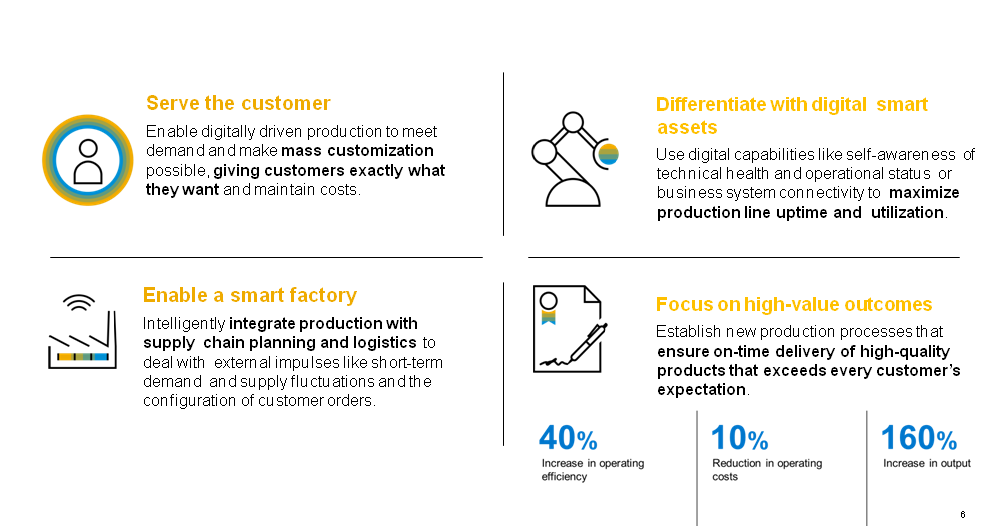

Why digitization is important to manufacturing?

Photo courtesy: SAP

- Mirrored manufacturing processes.

Digitization helps when an organization has multiple locations. With digitization they can replicate the same process in every location they are based in.

Ever since globalization, organizations functioning manually without real-time, accurate Key Performance Indicator (KPI) awareness have been facing the issue of losing business to their more efficient competitors.

Digitization can offer much-needed relief to the industry because it’s much easier to share data and files across locations. With the advent of globalization, transferring data has become easier than ever before, seamless handing over of the work to a team located geographically away from you has become a reality while reducing or almost eliminating the dreaded downtime.

In a nutshell:

- Data can be shared in real-time

- Plants can request help online

- Processes can be replicated seamlessly and enforced over the network

- Anyone with the access rights can see the data whenever and wherever they want

- Quick and analytical decision-making.

Data handling and management go hand in hand with decision making, the quicker and more holistic data you receive about the whole process, the better the decision making for the people in charge. It also enables easier coordination between different departments and teams which leads to better business outcomes.

Summary

As we move towards Industry 4.0, manufacturing is only going to get better, more analytical and efficient. In this day and age manufacturing needs to be able to respond quickly, efficiently and with precision to the demands of the supply chain, manufacturing execution operations and customer expectations. Their move towards digital transformation has to employ 3rd platform technologies such as mobile, analytics, blockchain, Internet of Things (IoT) and cloud.

If you would like to talk to our experts about how you can make your current manufacturing environment more efficient and productive, connect with us for a chat.