Success stories

Upgrade From Stone Age to New Age Technology

About Tremco

In 1928 William Treuhaft opened his small roofing materials manufacturing plant in Cleveland, Ohio, naming the company Tremco Manufacturing Company. Today, Tremco is an RPM International, Inc. affiliate company employing over 500 people and a leader in the construction industry.

Tremco consists of operating divisions specializing in the manufacture of sealants and waterproofing products for multiple structures including office buildings, stadiums, parking garages, single and multi-family homes, hospitals, high-rises and more.

Six-sided building solutions from Tremco Construction Products Group (CPG) delivers demonstrable performance at the lowest possible life-cycle cost, and stop leaks before they happen through ongoing maintenance programs. Building owners gain the peace of mind that comes with industry-leading system warranties — all from a single source platform.

What problem was Tremco facing?

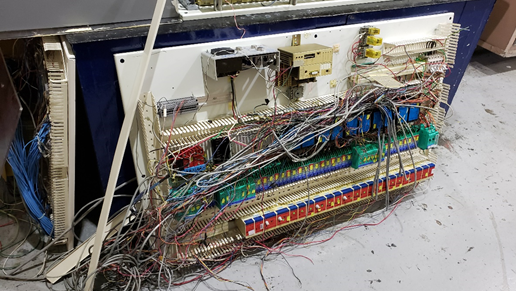

Tremco had some legacy PLCs to support their production process which they called “Dinosaur PLCs”. These PLCs had become obsolete and it was not possible to update them using present-day technology.

What were the effects of the problem?

Fear of Business Interruption

There was continuous concern within Tremco management of production interruption if these PLCs stop responding one day.

Downtime

Many times, after maintenance, the system took several reboots to start working normally. This resulted in an unexpected loss of production time, affecting OEE.

Difficult to Troubleshoot

Each time a problem occurred the supervisors on the plant floor had to call the IT specialist to resolve the issue.

Obsolete Technology

With the fast-paced electronics evolution, technology becomes obsolete after a few years. These existing PLCs had been in operation for more than 30 years, well past their prime and became obsolete. Service parts were not readily available in the market and very expensive

No compatibility

These PLCs were not compatible with current-day software and could not be upgraded.

Scope of Work Provided to Tremco:

- Upgrade existing Siemens PLC hardware

- Design & build the control panel to enable a quick switch over from the existing control panel to minimize downtime

- Upgrade existing SCADA application from Wonderware to Siemens WinCC

- Design new SCADA screens that were more operator friendly and reflected actual process layout and functionality

- Coordinate and oversee the hardwiring transition from the old to a new control panel

- Provide Startup and Commissioning services

- Provide post commissioning support

- Convert S5 PLC program to TIA Portal V16

How was the challenge resolved?

RTS’s Contribution:

- RTS proposed to have a Profinet architecture which eliminated all Profibus and Serial communication. RTS’s strategy allowed the client to save on additional communication hardware, as well as maintain the existing architecture for peer-to-peer communication with other existing PLCs.

- RTS also proposed improvements to SCADA architecture which resulted in allowing all processes to be monitored and operated from a single computer.

- SCADA security architecture was improved allowing security access to each process area without overlap for operators from different process areas.

Challenges experienced while implementing the solution

- During the commissioning stage, legacy field devices had compatibility issues with the new intrinsic barrier devices. This last-minute challenge caused RTS to work with Tremco’s Engineering staff to provide a cost-effective solution that would not affect their production schedule.

- The processes that were associated with the legacy PLC required temporary bridge programming until the new PLCs were fully online and SAT’d.

What were the Outcomes of the solution?

Contribution to Major Cleanup

Tremco now has a very reliable system and there is no fear of business interruption. Replacing the old PLCs contributed to a much-needed cleanup on the shop floor.

Easy to Troubleshoot

The newly implemented PLCs are very easy to troubleshoot and it has minimized the requirements of calling in an IT specialist to resolve the issue.

Compatible

The new software and hardware are very much compatible with modern-day technology and it is very easy to implement new changes in the future.

Nearly no Downtime

The new system requires very less maintenance, hence nearly no downtime in the production, resulting in high productivity.

About RTS

RTS Consulting – Automation specializes in providing high-value control systems to automate manufacturing cells and processes using the latest industrial technologies. RTS’s 30+ years’ manufacturing experience, across a wide range of industries, has positioned it well to help companies identify opportunities for improvements in all operational areas to achieve global manufacturing excellence.

Whether you want to reduce operating costs, improve efficiencies, add capacity or improve your competitive position in the market, RTS Consulting – Automation is your single-source solution provider for all of your manufacturing automation control and digital transformation needs.

Why Tremco chose RTS?

Tremco chose RTS because of its deep industrial automation experience providing high-value control system solutions to automate manufacturing cells and processes using the latest industrial technologies.

Along with this, RTS had a great Onsite Support system:

- RTS provided onsite support during the transition between the PLC and SCADA upgrades. RTS was able to provide a quick response (within 1 hour) after any client reported issues.

- RTS’s employees trained and worked with Tremco’s Operations team to make them comfortable with the operation of the new SCADA system.

Some comments from Tremco’s team

This project required both Hardware and Software components – RTS had experience working on PLC and SCADA technology software and hardware platforms and enveloped these services for Tremco which made it very easy to co-ordinate comparable to separate vendors.

Although it took more than expected time to complete the project due to unanticipated circumstances, but we are highly satisfied with the approach that was adapted to execute this project.

RTS is our trusted partner for the past 16 years. We have a trust and reliability relationship with them and would like to partner with them for our upcoming ventures.